Guest Editorial

21 March 2017 – Detroit Wrecker Sales prides itself on interactions with those in the towing & recovery industry. Whether you have purchased one of their products or not, Detroit Wrecker strives every day to not only build the highest quality product on the market, but provide the men & women of this industry with knowledge about any towing equipment and resources available to them to make their jobs easier. Lee Dunn & Mike Farrell of Detroit Wrecker Sales represent a new generation of towing equipment manufacturers and their business model is to promote knowledge and understanding about the products being used in the field of the towing industry. As the owners of Detroit Wrecker Sales, they are leaving a lasting impression by interacting with towers and repossession agents nationwide by directly helping them solve their problems with their equipment. Their cell phone numbers are public knowledge, Mike’s being 248-249-8100 and Lee’s 248-342-1701 and  they will help anyone anytime resolve an issue they are facing a with any brand of towing equipment. Their

they will help anyone anytime resolve an issue they are facing a with any brand of towing equipment. Their  message in this article is simple: know your equipment inside & out. These guys are giving us a manufacturer’s perspective on how equipment should be maintained & what each individual operating it should be aware of.

message in this article is simple: know your equipment inside & out. These guys are giving us a manufacturer’s perspective on how equipment should be maintained & what each individual operating it should be aware of.

Owners, if you are reading this we highly recommend sharing this article with your drivers. Questions any driver should know before operating your expensive truck & equipment: How is the unit powered? What is the definitive relationship between the function on your controls to which cylinders, which hoses, and which connections on the valve? What is the operating pressure of the hydraulic system currently? What is it supposed to be? When was the pressure last checked? When was the equipment last inspected & greased by owner or mechanic? What is the equipment rated for and Gross Vehicle Weight Rating of truck? If you are paying a driver to tow or repossess cars, they should be competent enough to answer those questions before they cost you thousands of dollars per year in maintenance.

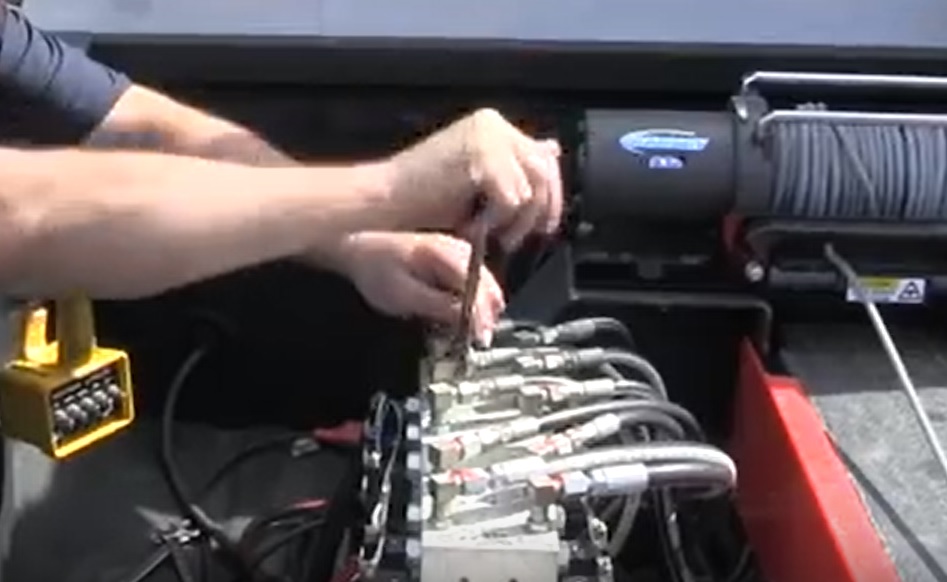

Starting with your hydraulic system, there are three common ways that your towing equipment can be powered: PTOs, Clutch Pumps, or Electric Over Hydraulic Pumps. Starting with PTOs, they are most common on large wreckers and most flatbeds and are always mounted to the side of the transmission with a pump that circulates fluid from the valve, to the cylinders and hydraulic tank. Most common things to keep an eye on are check for leaks and noticing weird noises before the problems escalate into major repairs. Detroit Wrecker recommends installing a buzzer to prevent someone from ever driving with the PTO engaged as that can cause an expensive repair. Clutch Pumps mount directly to the engine and function almost the same as a PTO. They are very popular on light duty wreckers and repossession applications. Whether you have a PTO or clutch pump, you also have both a valve and a hydraulic fluid tank. One thing to note is that your hydraulic tank should have a volume of 2-1/2 times your gallons per minute (GPM) on the pump. So, if you have an 11 GPM pump, you need a tank with at least 27.5 gallon reservoir capacity. Operators should be capable of learning which section performs each function on the valve, checking the system pressure at least once a month, and keeping all areas clean to easily notice if leaks develop.

Electric Over Hydraulic Pumps are popular in the light duty wheel lifts added to pick-up trucks due to their small cylinder sizes for fluid volume. In regards to electric over hydraulic pumps, you should know that they operate independently of drivetrain of vehicle. Any operator should know which valve section performs which function, check the pressure of the system once a month, and keep areas clean to resolve leaks before they happen. Detroit Wrecker also recommends having circuit breakers & fuses in line with batteries to quickly determine power shortages during repairs.

The rest of any towing equipment hydraulic system is composed of check valves, hoses, and cylinders. Check valves are a safety precaution to prevent a cylinder from moving when it is not supposed to such as moving down the road or when the vehicle is parked and no human interaction causes it. They can become defective over time and cause cylinders to drift or stop moving completely. Check valves should always be inspected during process of elimination when a hydraulic issue arises. Hoses transfer the fluid from location to location and we recommend tightening all hoses and marking the fitting connections with a paint marker so it is very easy to detect in future if hose has loosened. It is important to review conditions of hoses on regular basis, to make sure not leaking or damaged from contact with steel components. The last component of your hydraulic system is the cylinders, which we recommend keeping cylinders clean to easily detect leaks when they develop. Also critically important is visually inspecting pins to make sure they are all in proper placement and tight.

The rest of any towing equipment hydraulic system is composed of check valves, hoses, and cylinders. Check valves are a safety precaution to prevent a cylinder from moving when it is not supposed to such as moving down the road or when the vehicle is parked and no human interaction causes it. They can become defective over time and cause cylinders to drift or stop moving completely. Check valves should always be inspected during process of elimination when a hydraulic issue arises. Hoses transfer the fluid from location to location and we recommend tightening all hoses and marking the fitting connections with a paint marker so it is very easy to detect in future if hose has loosened. It is important to review conditions of hoses on regular basis, to make sure not leaking or damaged from contact with steel components. The last component of your hydraulic system is the cylinders, which we recommend keeping cylinders clean to easily detect leaks when they develop. Also critically important is visually inspecting pins to make sure they are all in proper placement and tight.

The next major series of components worthy of mention is the vehicle’s electrical system. Many people are intimidated by even the word “electrical” however most tow trucks and wrecker have very simple electrical systems. For those customers with valves that have electrical solenoids, for instance like on most new wreckers, best recommended maintenance is making sure connections are clean and the contact is tight and secure. If your unit has a handheld controller, make sure you have schematic of color coded wiring in your glove box before you actually need it! Verify switch connections are tight and visually inspect cord to make sure it is not getting damaged anywhere between the cab and the valve body. Detroit Wrecker recommends keeping a spare switch on hand so that way if one fails you already have one available. Almost all trucks have auxiliary or additional switches upfitted into the cab and Detroit Wrecker recommends inspecting monthly to make sure connections are still tight and if the switch becomes loose or takes multiple movements to engage replace quickly before that switch causes your entire unit not to operate!

The lighting on the equipment is very easy to understand as well. Factory feeds from the truck manufacturer cover all of the basic DOT requirements such as stop tail turn, reverse, and running lights. Those feeds meet inside the junction box and the up fitter’s wiring goes from there to all of the lights on the body of the wrecker or flatbed. Any additional work lights or flashing lights go from feeds in the junction box to a function on one side and a power source, a ground, and a switch on the other side. We recommend making sure the operator has an understanding of your junction box layout and which lighting functions are wired into it. Cleanliness applies here as well and again verifying monthly that all connections are secure & tight. Make sure electrical connectors are suitable for your climate conditions. Corrosion can cost thousands of dollars in electrical repair over time!

Here is a simple process of elimination to determine why a light is not working. Take an electrical tester to confirm whether there is power at the wire behind the light. If there is power then it is just the light itself. If there is no power at that wire, check at the junction box. If there is power there then either the connection is bad or there is damage to the wire between the light and the junction box. If there is no power at the junction box, there is a fault in the wire or switch coming from the cab and/or a fuse is blown on the truck.

The next critical area of your equipment has to do with the functionality of what it does. Detroit Wrecker recommends greasing all of your  equipment weekly at the wheel lift crossbar pivot, bed pivot (flatbeds only) and all other cylinder pivot pins. Keeping the pins greased will make removing them very easy and inexpensive compared to them being corroded & frozen in place. Making sure that all of the pins are properly seated in position, bushing intact, and not dangerously loose should be part of a weekly inspection. This keeps your equipment not only functioning but safe, and safety is always a factor. If a cylinder pin rotates its way out of position there could be a disastrous situation. If your unit has a winch, every week the oil should be inspected, verify winch tensioner is working and cable is not damaged, and lubricate the free spool to insure no future problems with it. If your unit has plastic wear pads, they need to be inspected and replaced as needed because as they become looser, it becomes more unsafe. Having a unit that is fit and tight is how the equipment was designed to perform. Replacing the wear pads when necessary and properly greasing the equipment will yield a consistent result in performance.

equipment weekly at the wheel lift crossbar pivot, bed pivot (flatbeds only) and all other cylinder pivot pins. Keeping the pins greased will make removing them very easy and inexpensive compared to them being corroded & frozen in place. Making sure that all of the pins are properly seated in position, bushing intact, and not dangerously loose should be part of a weekly inspection. This keeps your equipment not only functioning but safe, and safety is always a factor. If a cylinder pin rotates its way out of position there could be a disastrous situation. If your unit has a winch, every week the oil should be inspected, verify winch tensioner is working and cable is not damaged, and lubricate the free spool to insure no future problems with it. If your unit has plastic wear pads, they need to be inspected and replaced as needed because as they become looser, it becomes more unsafe. Having a unit that is fit and tight is how the equipment was designed to perform. Replacing the wear pads when necessary and properly greasing the equipment will yield a consistent result in performance.

Detroit Wrecker recommends keeping the following tools in the cab of your truck: electrical tester (Power Probe), wrench wet (particularly 11/16’’ and 5/8’’ wrenches), a gallon of hydraulic oil, flashlights, and a pressure gauge.

Weekly, the operator of the truck should go over the following details to insure that the equipment performs as its designed: pressure of hydraulic system, grease & lubrication of unit, connections of hose fittings, pivot pins for correct fitment & movement, winch area, electric solenoids, and the valve area for leaks.

Detroit Wrecker wants all owners and operators to be successful out in the field and that requires being prepared. Any business owner wants consist results in performance from their personnel, equipment, and their relationships with other entities. Follow these recommendations and Detroit Wrecker guarantees you will have the best result for your truck no matter what brand it is. Detroit Wrecker is known for building the best equipment on the road and high customer satisfaction. Contact them anytime for questions or a quote to build the truck of your dreams. 313-835-8700 or sales@detroitwrecker.com